![different-types-of-carpenter-infographic-plaza]()

![Woodworking Expertise and Carpentry Tools You Should Know different-types-of-carpenter-infographic-plaza-thumb]()

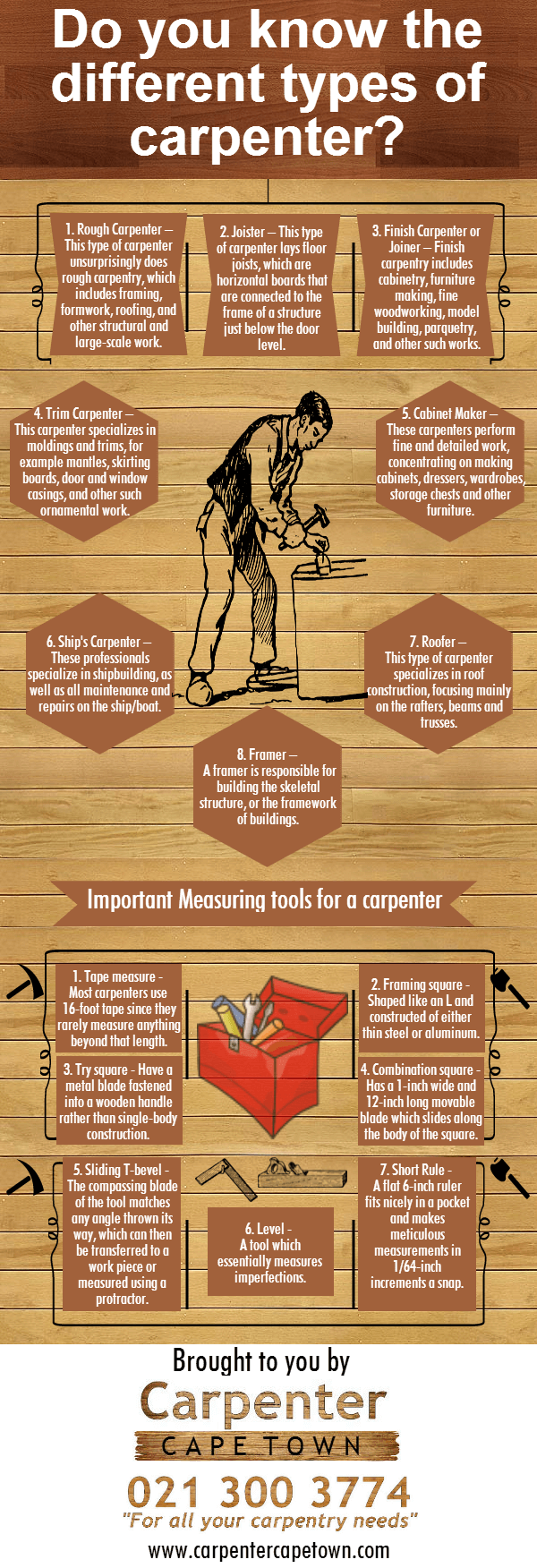

Carpentry is one of the oldest professions known to mankind. From the stone age days, through the industrial revolution, woodworking has evolved significantly. We now have carpenters specializing in different aspects of the trade depending on their skill set. Below are some of the popular woodworking specialties.

One of the most popular specialties the ship’s carpenter, whose main work is building, repair, and maintenance of ships/boats. He not only specializes in wooden ships but steel ones too. This carpenter knows the right timber to work with and how to attain the perfect finish.

The roofer follows next with his experience in roof construction. His field of expertise include beams, trusses, and rafters. He works closely with building contractors.

A framer is a carpenter who creates the skeletal structure or framework of your building as designed by an architect. He takes measurements, calculates the best angles, installs beams and joins them accordingly.

All the woodworkers mentioned above will need the input of a rough carpenter. He does the framing, formwork, and roofing too. Anything to do with structural, and large-scale rough carpentry, he is your guy.

From the rough carpenter, you may want to pass through the trim carpenter for molding and trimming of your timber. However, he also does trimming of mantles, skirting boards, and door & window casings.

We then have the cabinet maker, who, as his name suggests makes cabinets, wardrobes, dressers and storage chests. His work is almost similar to the finish carpenter/joiner only that the joiner delves deeper into fine woodworking, model building, parquetry and furniture making.

Now, for all these carpenters, nothing would be more important to them than their tools of the trade. More specifically the measuring devices. The equipment enhances efficiency and makes the carpenter’s work easier.

Top of the list of measuring tools is the tape measure. It is the most popular. The majority of carpenters walk around with it in their pocket. It can measure distances of up to 16 ft. Next are the squares. Namely, try square, framing square, and combination square. The try square is used to measure the accuracy of a right angle when checking the straightness of a surface to an adjoining surface. The same goes for a framing square, only that it is made of thin steel or aluminum.

A combination square, on the other hand, serves several purposes which include checking right and 450 angles. It is made up of a 1-inch wide and 12-inch movable blade.

For meticulous measurements, the carpenters make use of a short rule. It is 6-inch long, therefore, can be carried around with ease. When it comes to imperfections, the level takes care of business while the T-bevel measures angles that are neither 900 nor 450.

![different-types-of-carpenter-infographic-plaza]()

Source:

http://www.carpentercapetown.com/blog/

Carpentry is one of the oldest professions known to mankind. From the stone age days, through the industrial revolution, woodworking has evolved significantly. We now have carpenters specializing in different aspects of the trade depending on their skill set. Below are some of the popular woodworking specialties.

One of the most popular specialties the ship’s carpenter, whose main work is building, repair, and maintenance of ships/boats. He not only specializes in wooden ships but steel ones too. This carpenter knows the right timber to work with and how to attain the perfect finish.

The roofer follows next with his experience in roof construction. His field of expertise include beams, trusses, and rafters. He works closely with building contractors.

A framer is a carpenter who creates the skeletal structure or framework of your building as designed by an architect. He takes measurements, calculates the best angles, installs beams and joins them accordingly.

All the woodworkers mentioned above will need the input of a rough carpenter. He does the framing, formwork, and roofing too. Anything to do with structural, and large-scale rough carpentry, he is your guy.

From the rough carpenter, you may want to pass through the trim carpenter for molding and trimming of your timber. However, he also does trimming of mantles, skirting boards, and door & window casings.

We then have the cabinet maker, who, as his name suggests makes cabinets, wardrobes, dressers and storage chests. His work is almost similar to the finish carpenter/joiner only that the joiner delves deeper into fine woodworking, model building, parquetry and furniture making.

Now, for all these carpenters, nothing would be more important to them than their tools of the trade. More specifically the measuring devices. The equipment enhances efficiency and makes the carpenter’s work easier.

Top of the list of measuring tools is the tape measure. It is the most popular. The majority of carpenters walk around with it in their pocket. It can measure distances of up to 16 ft. Next are the squares. Namely, try square, framing square, and combination square. The try square is used to measure the accuracy of a right angle when checking the straightness of a surface to an adjoining surface. The same goes for a framing square, only that it is made of thin steel or aluminum.

A combination square, on the other hand, serves several purposes which include checking right and 450 angles. It is made up of a 1-inch wide and 12-inch movable blade.

For meticulous measurements, the carpenters make use of a short rule. It is 6-inch long, therefore, can be carried around with ease. When it comes to imperfections, the level takes care of business while the T-bevel measures angles that are neither 900 nor 450.

Carpentry is one of the oldest professions known to mankind. From the stone age days, through the industrial revolution, woodworking has evolved significantly. We now have carpenters specializing in different aspects of the trade depending on their skill set. Below are some of the popular woodworking specialties.

One of the most popular specialties the ship’s carpenter, whose main work is building, repair, and maintenance of ships/boats. He not only specializes in wooden ships but steel ones too. This carpenter knows the right timber to work with and how to attain the perfect finish.

The roofer follows next with his experience in roof construction. His field of expertise include beams, trusses, and rafters. He works closely with building contractors.

A framer is a carpenter who creates the skeletal structure or framework of your building as designed by an architect. He takes measurements, calculates the best angles, installs beams and joins them accordingly.

All the woodworkers mentioned above will need the input of a rough carpenter. He does the framing, formwork, and roofing too. Anything to do with structural, and large-scale rough carpentry, he is your guy.

From the rough carpenter, you may want to pass through the trim carpenter for molding and trimming of your timber. However, he also does trimming of mantles, skirting boards, and door & window casings.

We then have the cabinet maker, who, as his name suggests makes cabinets, wardrobes, dressers and storage chests. His work is almost similar to the finish carpenter/joiner only that the joiner delves deeper into fine woodworking, model building, parquetry and furniture making.

Now, for all these carpenters, nothing would be more important to them than their tools of the trade. More specifically the measuring devices. The equipment enhances efficiency and makes the carpenter’s work easier.

Top of the list of measuring tools is the tape measure. It is the most popular. The majority of carpenters walk around with it in their pocket. It can measure distances of up to 16 ft. Next are the squares. Namely, try square, framing square, and combination square. The try square is used to measure the accuracy of a right angle when checking the straightness of a surface to an adjoining surface. The same goes for a framing square, only that it is made of thin steel or aluminum.

A combination square, on the other hand, serves several purposes which include checking right and 450 angles. It is made up of a 1-inch wide and 12-inch movable blade.

For meticulous measurements, the carpenters make use of a short rule. It is 6-inch long, therefore, can be carried around with ease. When it comes to imperfections, the level takes care of business while the T-bevel measures angles that are neither 900 nor 450.

Source: http://www.carpentercapetown.com/blog/

Source: http://www.carpentercapetown.com/blog/